Sawyer Equipment

Destructive Weld Testing in Education: Fillet Weld Tester

Sawyer Mfg.’s 55-Ton Bend, Tensile & Fillet Tester Welding combines art and science, and as such, it’s crucial for educational environments to keep pace with technological advancements. In this context, Sawyer Manufacturing’s 55-Ton Fillet Weld Tester marks a significant addition to the tools available for welding education. Safety and Precision in Educational Settings The Fillet…

Read MoreSawyer Manufacturing Company:

Innovating Pipeline and Welding Solutions Since 1948 Sawyer Manufacturing Company, headquartered in Tulsa, Oklahoma, is a renowned name in the global market for pipeline and welding equipment. Established in 1948, Sawyer has been at the forefront of innovation in this sector, setting benchmarks for quality and durability in their products. Our Commitment to Innovation and…

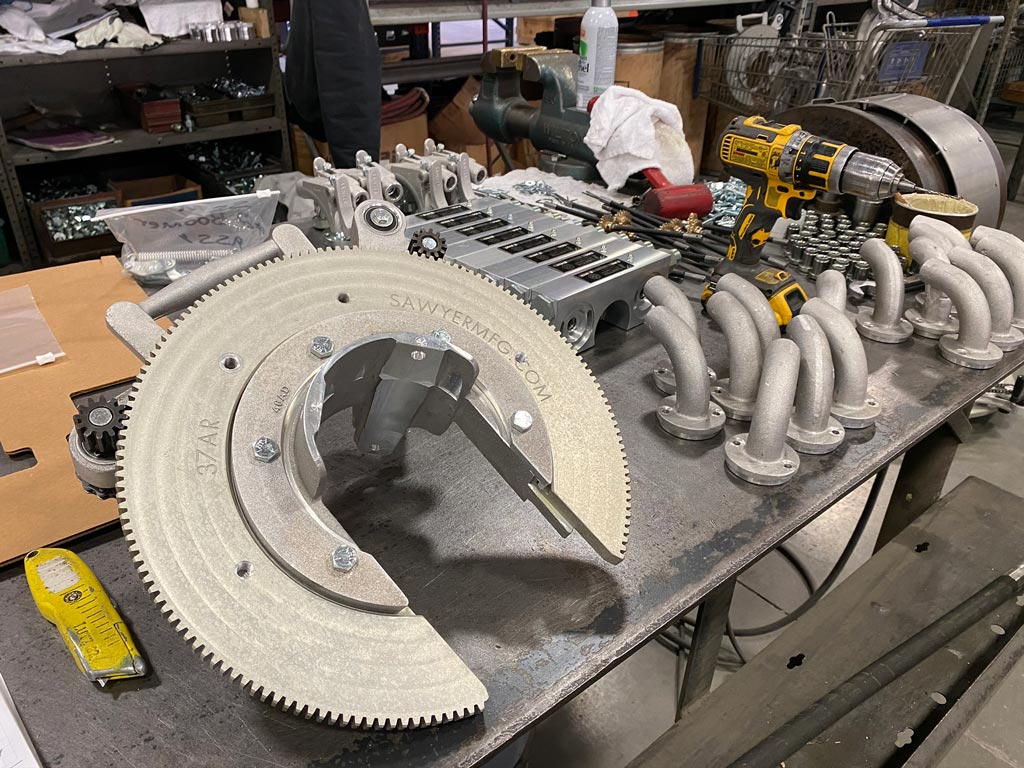

Read MoreA Cut Above: The Distinctive Craftsmanship of Sawyer Mfg Company’s Welding Tools

In the evolving panorama of welding technology, certain names stand out as pioneers, trailblazing the path for others to follow. At the vanguard of this list is the Sawyer Mfg. Company. Their array of welding tools not only adheres to the highest standards of the industry but also sets new ones. Let’s navigate through the…

Read MoreThe Importance of Quality: A Close Look at Pipe Beveling Equipment from Sawyer Mfg. Company

Pipe beveling equipment is paramount when it comes to pipe beveling – a crucial step in the pipe joining process. The equipment you use plays a pivotal role in determining the efficiency and precision of the end result.The demand for impeccable quality and durability pushes professionals towards top-tier equipment manufacturers. One such revered name in…

Read MoreOxy Fuel Cutting

Oxy fuel cutting has been around for more than a hundred years, and little has changed in the process since that time. The invention revolutionized the cutting and welding industries, and ultimately led to the development of today’s cutting torches, tips, flashback arrestors, etc. which have resulted in a much safer and more efficient way…

Read MoreRim Clamp solves pipe ovality issues

The oil and gas pipeline industry has had a challenging few years as a result of the global economic conditions and the low oil price. Contractors are increasingly looking for ways to reduce costs when budgeting for projects, and increasingly this has led to an increase in pipes being supplied from emerging markets. This, when…

Read MoreSawyer Saddle Machine

We are proud to announce the release of our newly designed Sawyer Saddle Machine. Listening to our customers Sawyer Manufacturing Company has been working with pipeline welders since 1948. In that time, we’ve seen the industry change and grow, and by listening to the welders using our equipment on the front line our range of…

Read MoreBattery Ready Motor Kit

Power and Precision – Without The Plug For years Sawyer Crawlers have been synonymous with accuracy and durability for pipe fitters across the world. Motorized Crawlers further enhanced this accuracy by removing the need to manually drive the machine; allowing operators to set the correct, consistent speed and generate a smooth cut all around. These…

Read MoreSawyer Spotlight: Grinder Holder

Working together to build better equipment In the Fall of 2013, Sawyer Manufacturing became involved with a program offered by Oklahoma State University in partnership with the Oklahoma Manufacturing Alliance to help Oklahoma manufacturers design new products. The result was Sawyer’s Grinder Holder. OSU students created the designs and drawings of the holder, and the…

Read MoreSawyer Spotlight

Quick Set Beveling Machine When it comes to pipeline welding tools and accessories, there are many options. That’s why Sawyer Manufacturing is committed to designing and building equipment that is unmatched in versatility and usability. The Quik Set Beveling Machine is no exception. With a unique, lightweight design that allows speed and efficiency in the…

Read More

USA / EN

USA / EN Middle East

Middle East México / Espanol

México / Espanol