SPACER SYSTEM -

3 pipe sizes in a single spacer

SMOOTH CUT -

The smoothest travel of any saddle unit on the market

SIZES -

4 Machines cut pipe sizes 1.5" - 20"

FEATURES

- For pipe sizes ranging from 1.5″-20″

- 4 machine sizes

- Spacers are designed to accommodate 3 pipe sizes

- #0, #1, and #2 machines cut 4 specific pipe sizes and come with 4 Spacers

- #3 machine cuts 5 specific pipe sizes and comes with 8 Spacers

- Familiar, open design for easy placement over the pipe

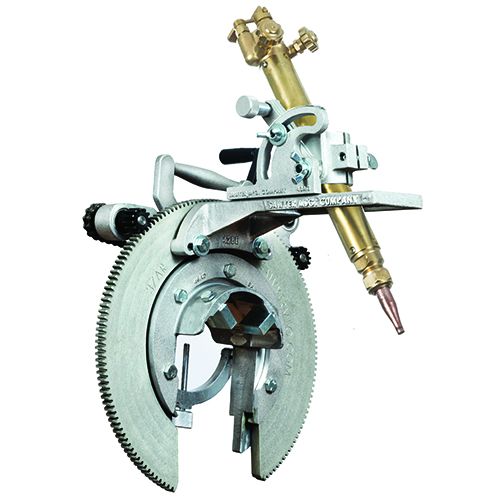

- Can be used with most oxy/fuel or plasma torches

- Optional accessories to meet any beveling requirement

- Battery Ready Motor Kit optional

- Torch not included

- Manufactured in the USA

- 1 year warranty

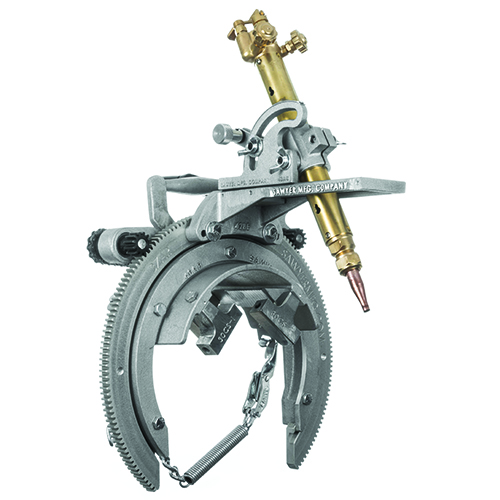

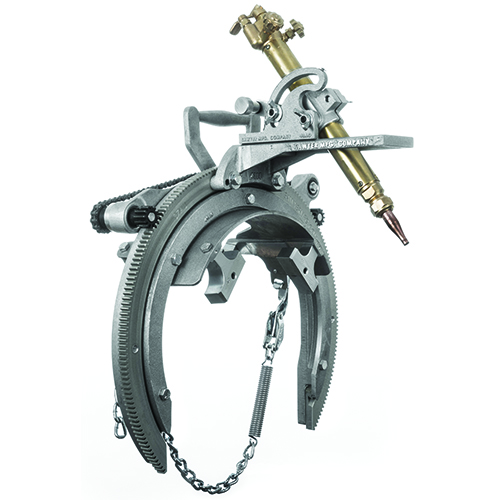

Sawyer Saddle Machine

Model SSM

Sawyer Beveling Machines are proudly 100% MADE IN THE USA, using locally sourced materials. This guarantees quality and faster delivery times than our competitors, and also supports the American manufacturing industry.

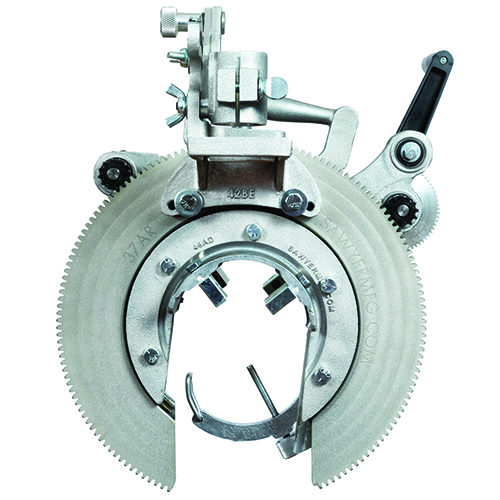

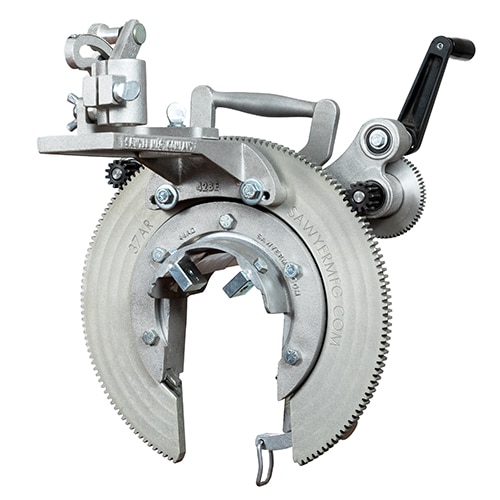

The Sawyer Saddle Machine (SSM) is a saddle beveling machine that incorporates all the well-known features of a traditional saddle machine while delivering the quality that Sawyer is known for. Its open-frame design and spacer system make it easy for operators to use and learn, improving efficiency and productivity. The machine is available in four different sizes to accommodate popular pipe sizes ranging from 1.5” to 20” OD, offering a versatile solution for various pipe cutting needs. The spacer system is efficient, allowing for adjustment between pipe sizes, and can accommodate three different pipe sizes within a single spacer.

Each SSM machine comes with four or eight spacers, depending on the size, and can cut four to five distinct pipe sizes. These lightweight machines are made of cast aluminum and feature a bolt-together frame that can be easily repaired. The Classic Torch Arm, which adjusts easily to the desired angle and prevents blowholes by moving to and from the cutline, comes standard with each machine. Setup is easy with the Saddle Machine’s open-frame design; simply place it over the pipe and secure it with a locking boomer.

Sawyer takes pride in building the SSM, along with all our beveling machines, at our Tulsa, Oklahoma facility. By designing and manufacturing the product in-house, Sawyer has been able to thoroughly test every aspect of the machine and ensure that each unit leaves the facility calibrated and tested for quality assurance. The result is a saddle beveling machine with the smoothest travel on the market, delivering the reliable and precise cuts that pipefitters and welders have come to expect from Sawyer.

Machine Sizes:

- #0: 1.5″-4″

- #1: 3″-8″

- #2: 6″-12″

- #3: 12″-20″

USA / EN

USA / EN Middle East

Middle East México / Espanol

México / Espanol