Pipeline Pigging

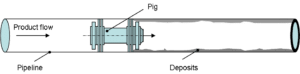

Special tools known as in-line inspection tools or smart pigs are sent through pipelines to inspect the pipe for damage or corrosion that could lead to leaks.

[image credit:www.neb-one.gc.ca | Google image search]

Spill Prevention

The recent oil spilled from a pipeline in California might bring to mind questions regarding the safety of pipelines. As previously discussed, pipelines are one of the safest, cheapest and most reliable methods of transporting oil and gas products. However, as with anything, accidents do happen, despite everyone’s best efforts. What are those best efforts, though? How do pipeline operators prevent accidents like this? The answer, my friends, is found in the pigs.

Pigs: In-line inspection tools

Well, pigs are just one of the ways accidents are prevented. Other methods are frequent inspections, cathodic systems that prevent corrosion, and quality construction techniques in the first place, including appropriate pipe fit up, pipe bending, pipe beveling, pipe lifting, and weld testing.

Back to the pigs…and no, we aren’t referring to the mud-wallowing, bacon-making animals. Instead, these pigs are devices inserted into pipelines by pig launchers. Yes, pig launchers. Upon launching, pigs and smart pigs, propelled by the flow of oil and gas, travel through pipelines, doing many tasks. One of these tasks is inspecting the conditions of pipes and returning data. Once at the end of their routes, pigs come to a halt at pig catchers. Yes, pig catchers.

Through the wonders of magic, i.e. the science that allows the development of pig technology, operators are able to see weaknesses within pipelines and address any issues before they become problems or, in the worst cases, disasters.

That’ll do, pigs. That’ll do.

USA / EN

USA / EN Middle East

Middle East México / Espanol

México / Espanol