SMC Band and Crawler

As the diameter of pipeline pipe increases, a larger band is required. Sawyer Manufacturing Company develops and manufactures the SMC Band and Crawler to accommodate pipe up to 60” and larger.

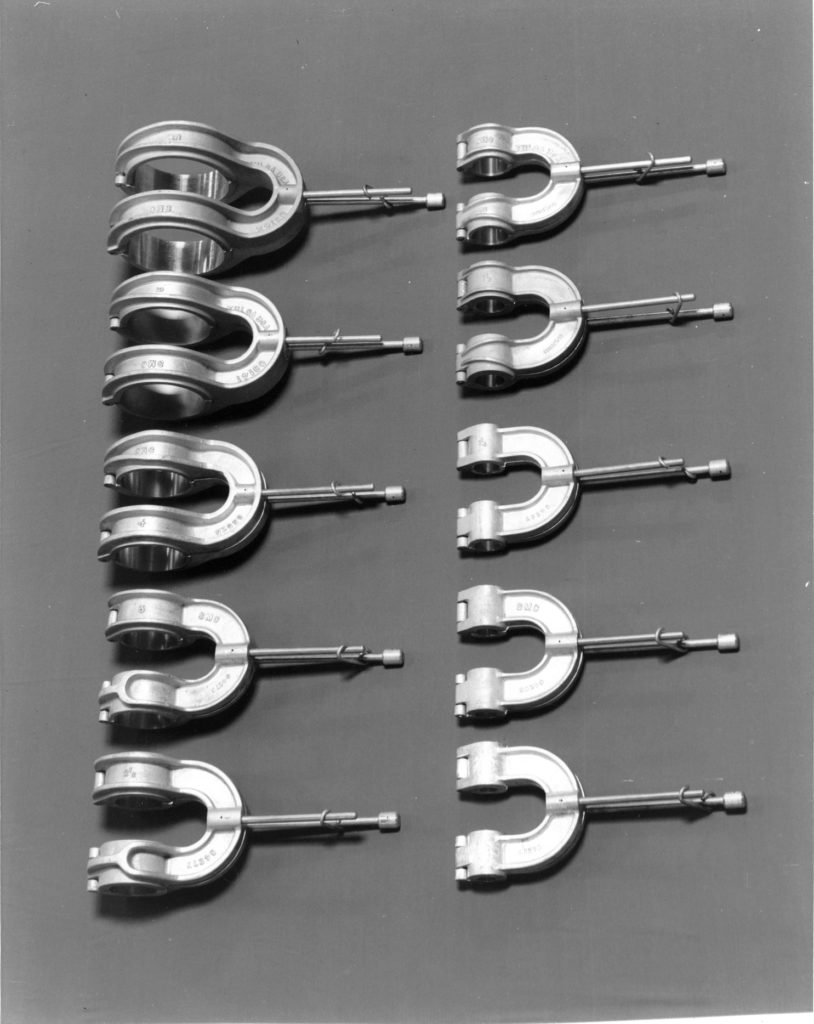

Read MoreAluminum Alignment Clamps

Sawyer Manufacturing Company develops and manufactures the Aluminum Line-Up Clamp as a small diameter clamp for pipe 6” and smaller. This clamp is popular for farmers and ranchers as well as pipeline welders.

Read MorePipeline Pigs

Sawyer Manufacturing Company develops and manufactures Pipeline Plugging Pigs and begins pig testing.

Read MoreEquipment Lines Expand

As the demand for oil grows, so does the pipeline size and infrastructure along with environmental regulations. Sawyer Manufacturing Company diversifies alongside the increasing demand, developing more than 25 equipment solutions for the expanding industry.

Read MoreTractor Bending Shoe

Sawyer Manufacturing Company develops and manufactures the Tractor Bending Shoe as an alternative for small diameter pipe to be bent effectively.

Read MoreExternal Ratchet Clamp

Pipelines were demanding a sturdier, quicker and more precise clamp on the job. Sawyer Manufacturing Company responded with the first generation of the External Ratchet Clamp.

Read MoreThomas G. Sawyer on the Pipeline

Thomas G. Sawyer, son of Red Sawyer, at age 14, begins working on the pipeline as a laborer. This time spent working on the pipeline would later prove beneficial when designing equipment for the pipeline.

Read MorePipe Grinder

Sawyer Manufacturing Company develops and manufactures the Pipe Grinder, which creates the land after the bevel.

Read MoreCrose Forms MJ Crose International

Sawyer Manufacturing Company continues to manufacture equipment as Crose Manufacturing merges to form MJ Crose International.

Read MoreCoupon Cutter

The Coupon Cutter is developed and manufactured to cut a consistent, quick sample for testing welds. On the pipeline, welders require an AC power source for the jobsite. Sawyer Manufacturing Company introduces Power Buggies, an AC generator. Slag Busters to clean welds between passes are also developed and released.

Read More

USA / EN

USA / EN Middle East

Middle East México / Espanol

México / Espanol