FEATURES

- Performs guided bend and tensile strength pull tests

- Accurately perform tests up to 100,500 pounds of pressure

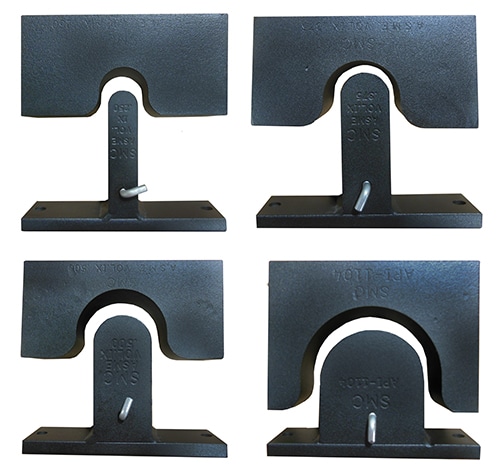

- Optional choice of die and plunger sets to meet ASME or API code

- Comes standard with .375 ASME die and plunger set and 1/4-1/2″ pulling jaws

- 3 pulling jaw size options

- Includes a liquid-filled, certified gauge with high level indicator, 2-speed manual pump, (1) Set of pulling jaws, (1) Die and plunger set, (1) carrying case

- Quality constructed for rugged strength

- Transportable – heavy but can be moved

- Manufactured in the USA

Sawyer’s 55 Ton Bend and Tensile Tester

Model 273-55

When maximum strength matters, the Sawyer 55 Ton Guided Bend and Tensile Tester delivers unmatched performance for weld certification, qualification, and quality control. Engineered for high-capacity testing in demanding environments, this machine offers precision, power, and rugged reliability for those who need to evaluate welds under serious stress.

The 55 Ton unit is built for destructive testing at scale—designed to expose weaknesses, verify structural integrity, and confirm code compliance for critical welding applications. While smaller testers are suitable for standard test coupons, the 55 Ton is the right choice when you’re testing larger weldments, tougher materials, or high-spec industrial joints. It’s capable of applying up to 110,500 pounds of hydraulic force, making it ideal for heavy-duty tension pulls and guided bend tests in pipeline, structural steel, and pressure vessel applications.

This dual-frame system allows for both bend and tensile testing with fast setup, giving operators the flexibility to switch between ASME and API procedures in minutes. It comes standard with a .375″ (3/8″) ASME die and plunger set, pulling jaws, a certified liquid-filled gauge with high-level indicator, and a two-speed manual pump—all packed into a rugged carrying case for secure transport and storage. Additional die and plunger sets in .250″, .500″ ASME and API 1104 configurations are available to meet your testing needs. For high-volume testing operations, the unit is fully compatible with electric or pneumatic Power Team pumps.

Despite its high capacity, the 55 Ton Tester maintains mobility for field use. Though heavier than other models, it’s still transportable, making it a practical option for onsite weld inspections and mobile testing crews. Improved plating and powder coating offer superior corrosion resistance, ensuring durability through years of hard use in shop and field conditions alike.

Manufactured in the USA and backed by Sawyer’s reputation for dependable, industry-proven performance, the 55 Ton Guided Bend and Tensile Tester is trusted by professionals who can’t afford to compromise on accuracy or strength. If you’re testing high-spec welds in critical infrastructure, this machine delivers the confidence you need—test after test, job after job.

USA / EN

USA / EN Middle East

Middle East México / Espanol

México / Espanol