FEATURES

- Performs guided bend and tensile strength pull tests

- Accurately perform tests up to 51,500 pounds of pressure

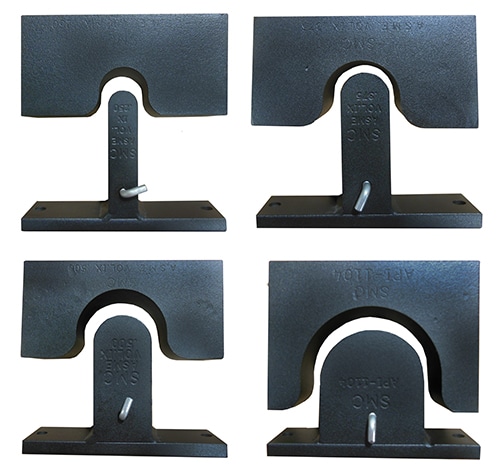

- Optional choice of die and plunger sets to meet ASME or API code

- Comes standard with .375 ASME die and plunger set and 1/4-1/2″ pulling jaws

- 3 pulling jaw size options

- Includes a liquid-filled, certified gauge with high level indicator, 2-speed manual pump, (1) Set of pulling jaws, (1) Die and plunger set, (1) carrying case

- Quality constructed for rugged strength

- Transportable – heavy but can be moved

- Manufactured in the USA

Sawyer’s 25 Ton Bend and Tensile Tester

Model 273-25

For weld certification and qualification, the Sawyer 25 Ton Guided Bend and Tensile Tester delivers power, precision, and flexibility in one robust package. Built for both shop and field environments, this heavy-duty unit is engineered for destructive weld testing that meets the highest standards in the industry. Whether you’re testing for ASME or API code compliance, this machine provides the capability and confidence professionals rely on.

Destructive testing is essential to understanding how a welded joint performs under pressure—and the 25 Ton Tester is designed to simulate the extreme stress welds may face in real-world conditions. Guided bend tests help verify weld soundness by exposing discontinuities and flaws that could compromise structural integrity. Tensile pull tests take it a step further, measuring the actual breaking point of a weld to evaluate its strength, ductility, and overall performance. The 25 Ton unit’s dual-frame design allows both testing methods to be executed quickly and accurately from a single platform, eliminating the need for multiple machines.

This tester is equipped with Sawyer’s Liquid Gauge System and proven Power Team hydraulics, allowing it to exert up to 51,500 pounds of force with controlled precision. The system comes standard with a .375″ (3/8″) ASME die and plunger set, a two-speed manual pump, certified liquid-filled pressure gauge with high-level indicator, and a complete pulling jaw assembly—all stored in a rugged carrying case. Optional die and plunger sets are available in .250″, .500″ ASME, and API 1104 configurations. The system is also compatible with electric or pneumatic pumps for high-throughput environments.

Protected with corrosion-resistant plating and powder coating, this tester is built for years of reliable service, even in harsh conditions. Though substantial in capacity, it remains transportable—ideal for on-site inspections and mobile welding crews.

Manufactured in the USA with Sawyer’s trademark quality and innovation, the 25 Ton Guided Bend and Tensile Tester is the trusted solution for accurate, repeatable results in critical weld inspections. From training centers to pipeline job sites, this machine is built to perform when it matters most.

USA / EN

USA / EN Middle East

Middle East México / Espanol

México / Espanol